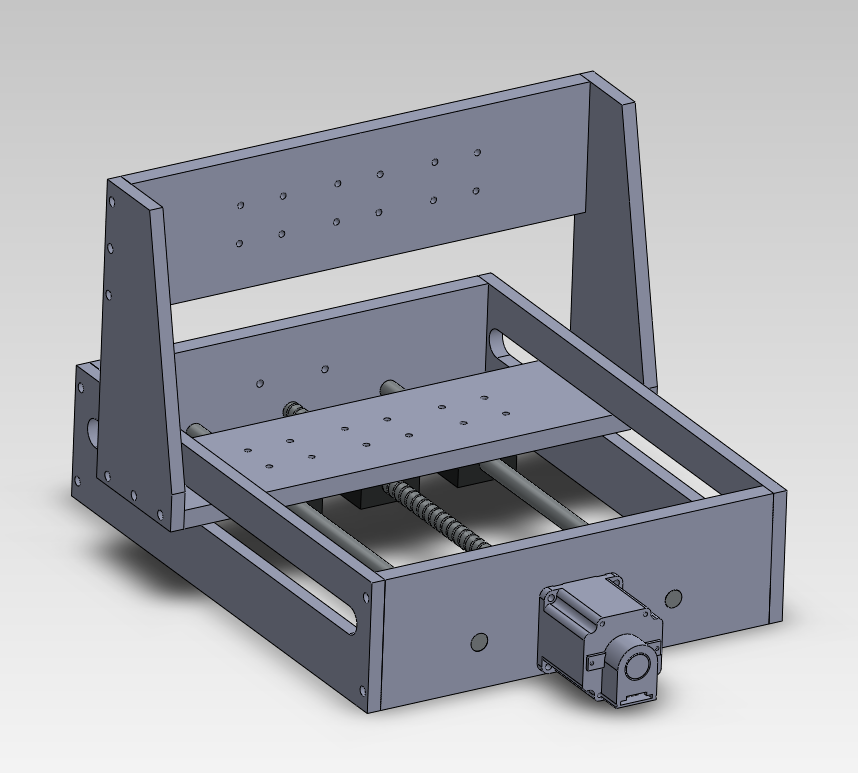

So far it looks like it's going to be a moving gantry design made of 3/8 and 1/2 Al plate. 12mm guide rods and rolled ball screws (vs the more expensive ground screws) Nema23 in the X and Y and nema17 for the Z.

We are going to keep substituting cheaper and cheaper parts till it cant hold 30 microns repeatability (about a mill). And than we will go back one step, and do a bulk order in parts. So far in single units the ball screws, which are probably the most expensive bits are 2 buck an inch and 80 bucks for the nut. Linear guide rod is about a buck an inch and the recirculating bearings are about $6~7.

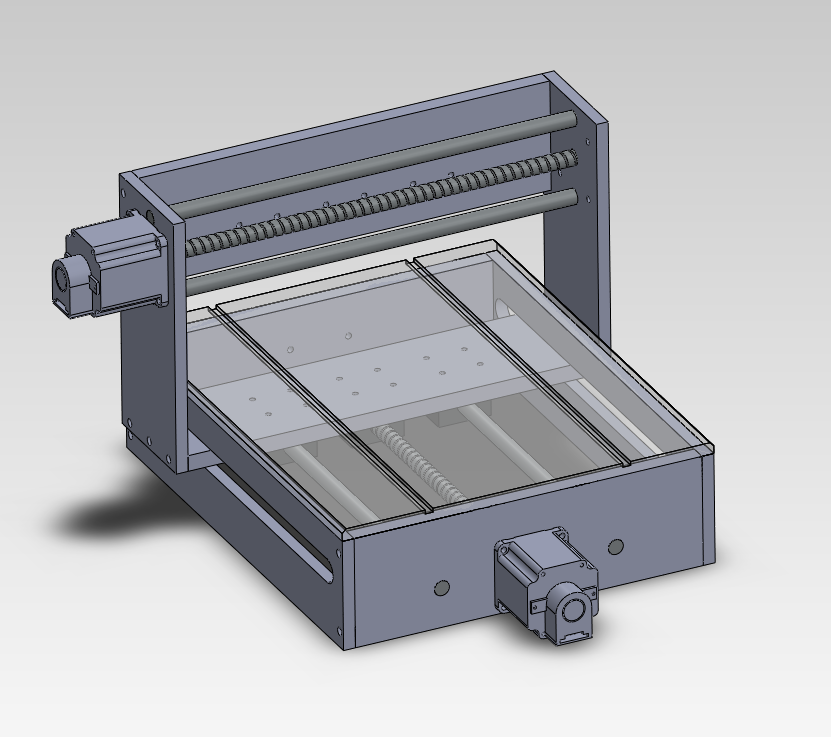

How the current CAD file looks: