through_hole_plating

Table of Contents

**Through hole plating of PCBs by acid copper.**

Formula:

**Ingredients:** .881 lb of crystal (CuS04)to each gallon of DI water .4 gal 35% sulfuric acid (H2SO4) .5ml hydrochloric acid (HCL) PEG 10mg/L leveler (found as laxative at RiteAid) Janus Green B as brigtner **Tips:** -Makes about 1.5gal -Can push about 25amps per sqft but we have been using 8amp/sqft as the plating seems brighter and more level -With a little agitation it seems we can push 10amps/sqft with out diminishing brightness. -Light sanding after activation is very important (1000 grit sandpaper)

Power Supply

DIY TPM http://www.dioda.ro/tutorial/TroughHole_MZingg/Welcome%20to%20the%20homebrew%20through%20plating%20machine.html http://www.dioda.ro/tutorial/TroughHole_MZingg/Welcome%20to%20the%20homebrew%20through%20plating%20machine2.html http://www.dioda.ro/tutorial/TroughHole_MZingg/Welcome%20to%20the%20homebrew%20through%20plating%20machine3.html http://www.dioda.ro/tutorial/TroughHole_MZingg/Welcome%20to%20the%20homebrew%20through%20plating%20machine4.html http://www.dioda.ro/tutorial/TroughHole_MZingg/Welcome%20to%20the%20homebrew%20through%20plating%20machine5.html http://www.dioda.ro/tutorial/TroughHole_MZingg/Welcome%20to%20the%20homebrew%20through%20plating%20machine6.html http://www.dioda.ro/tutorial/TroughHole_MZingg/Welcome%20to%20the%20homebrew%20through%20plating%20machine7.html

Concepts and Research

Pulse and pulse reverse plating—Conceptual, advantages and applications

{{:ea-v53-8-p3313.pdf}}

<code>

Role of Additives in the Bright Copper Plating from Acid Copper Sulfate Bath and the History

{{:0611.pdf}}

<code>

Aspect-Ratio-Dependent Copper Electrodeposition Technique for Very High Aspect-Ratio Through-Hole Plating

http://dx.doi.org/10.1149/1.2189238

The Theory behind Pulse Plating Reversal Current

{{:rp theory.pdf}}

<code>

Prototype of the Pulse Plating controller.

{{:platingcontroller.jpg}}

<code>

[[http://www.youtube.com/watch?feature=player_embedded&v=KTNuTv_IQp4|Another plating setup]]

through_hole_plating.txt · Last modified: by 127.0.0.1

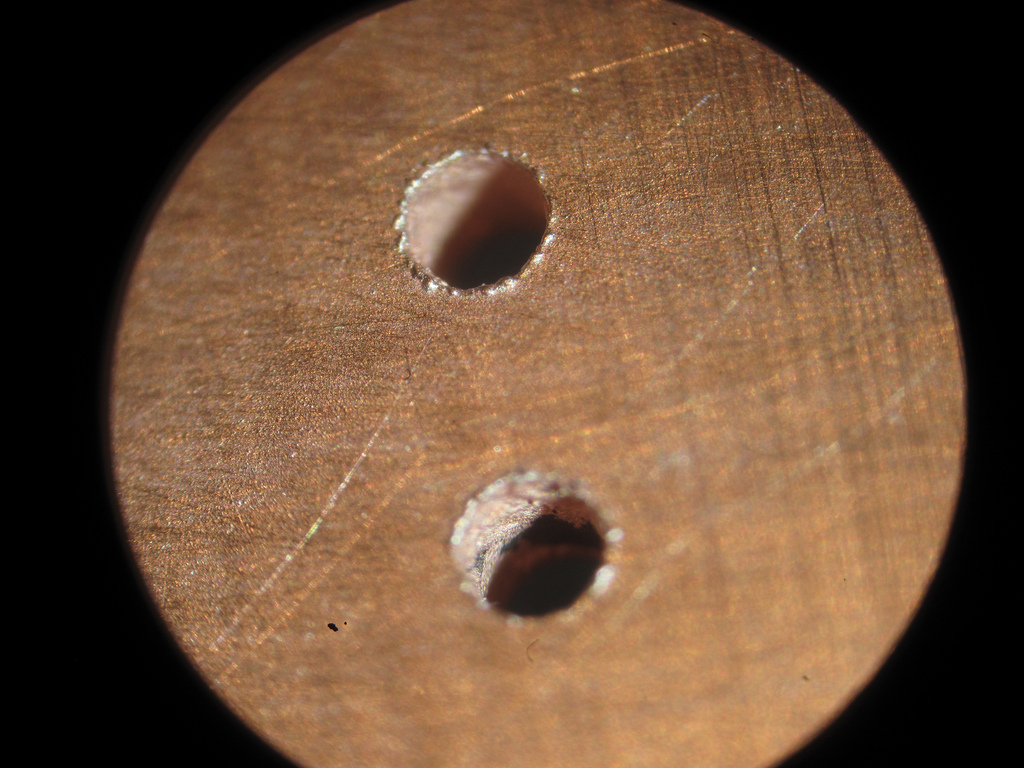

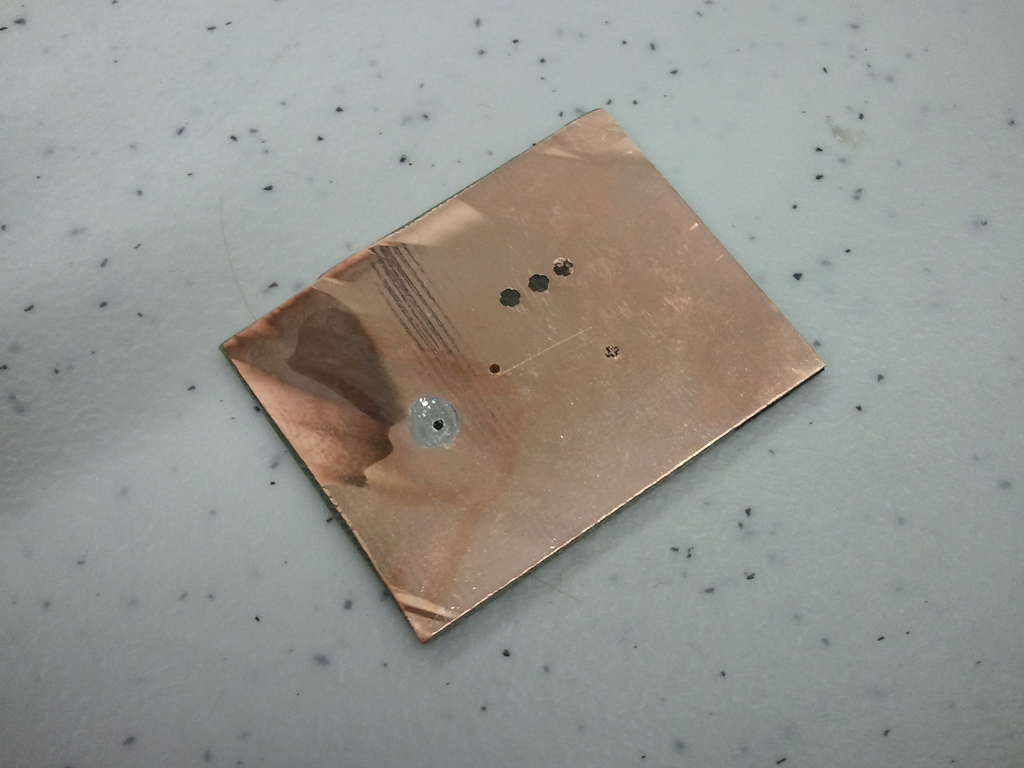

![thumb|microscope shot of hole, after plating.

The current calculation were a little off, hence the bumpy plating in the hole.]]

{{:throughholeplate3.jpg|none|400px|caption thumb|microscope shot of hole, after plating.

The current calculation were a little off, hence the bumpy plating in the hole.]]

{{:throughholeplate3.jpg|none|400px|caption](/lib/exe/fetch.php?media=thourhgholeplated2.jpg)